Current location:Home > seals and wipers >

seals and wipers

2025-08-14 09:10

2025-08-14 08:32

2025-08-14 08:25

2025-08-14 08:04

There are several types of inner hub seals available, each designed for specific applications and environments inner hub seal. Some seals are made of rubber or plastic, while others are made of more durable materials such as metal or synthetic rubber. The choice of seal will depend on factors such as the type of machinery, the operating conditions, and the level of sealing required.

inner hub seal. Some seals are made of rubber or plastic, while others are made of more durable materials such as metal or synthetic rubber. The choice of seal will depend on factors such as the type of machinery, the operating conditions, and the level of sealing required.

inner hub seal. Some seals are made of rubber or plastic, while others are made of more durable materials such as metal or synthetic rubber. The choice of seal will depend on factors such as the type of machinery, the operating conditions, and the level of sealing required.

inner hub seal. Some seals are made of rubber or plastic, while others are made of more durable materials such as metal or synthetic rubber. The choice of seal will depend on factors such as the type of machinery, the operating conditions, and the level of sealing required.

...

2025-08-14 07:58

2025-08-14 07:48

2025-08-14 07:44

2025-08-14 07:39

2025-08-14 07:35

2025-08-14 07:12

Latest articles

One of the key benefits of high pressure rotary shaft seals is their ability to operate in extreme conditions without compromising performance. They can withstand pressures of up to several thousand psi, making them ideal for applications such as hydraulic systems, compressors, pumps, and motors. In addition, these seals are resistant to wear and tear, ensuring long-lasting performance even in demanding environments.

Another benefit of the 20% 32% 6% oil seal is its ease of installation and compatibility with a wide range of machinery and equipment 20 32 6 oil seal. Whether used in automotive engines, hydraulic systems, or industrial pumps, this type of oil seal can be easily fitted onto the shaft without the need for specialized tools or equipment. Its universal design makes it a versatile solution for various applications, saving time and effort in the installation process.

20 32 6 oil seal. Whether used in automotive engines, hydraulic systems, or industrial pumps, this type of oil seal can be easily fitted onto the shaft without the need for specialized tools or equipment. Its universal design makes it a versatile solution for various applications, saving time and effort in the installation process.

20 32 6 oil seal. Whether used in automotive engines, hydraulic systems, or industrial pumps, this type of oil seal can be easily fitted onto the shaft without the need for specialized tools or equipment. Its universal design makes it a versatile solution for various applications, saving time and effort in the installation process.

20 32 6 oil seal. Whether used in automotive engines, hydraulic systems, or industrial pumps, this type of oil seal can be easily fitted onto the shaft without the need for specialized tools or equipment. Its universal design makes it a versatile solution for various applications, saving time and effort in the installation process.In addition to material, oil seals are also categorized based on their design and construction. The most common types include lip seals, mechanical seals, and hydraulic seals, each designed for specific applications and conditions. Lip seals are the most basic type and consist of a flexible lip that contacts the shaft to prevent leakage. Mechanical seals, on the other hand, utilize a rotary or stationary face to create a seal, while hydraulic seals are used in hydraulic systems to prevent fluid from leaking

20 35 7 oil seal.

20 35 7 oil seal.

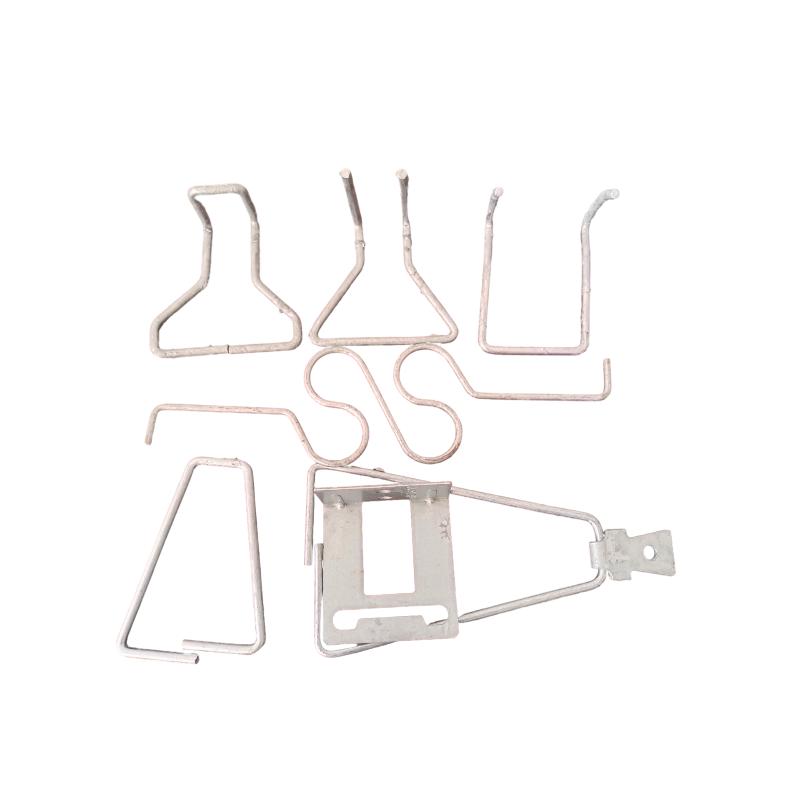

Drilling is the next step. With the marked spots, drill pilot holes into the inner leaf of the wall. The diameter and depth of the hole should match the size of the wall tie and its intended embedment depth. Be cautious not to damage the insulation or the outer leaf Be cautious not to damage the insulation or the outer leaf Be cautious not to damage the insulation or the outer leaf Be cautious not to damage the insulation or the outer leaf

Be cautious not to damage the insulation or the outer leaf Be cautious not to damage the insulation or the outer leaf installing wall ties.

installing wall ties.

Be cautious not to damage the insulation or the outer leaf Be cautious not to damage the insulation or the outer leaf

Be cautious not to damage the insulation or the outer leaf Be cautious not to damage the insulation or the outer leaf installing wall ties.

installing wall ties.